Repair

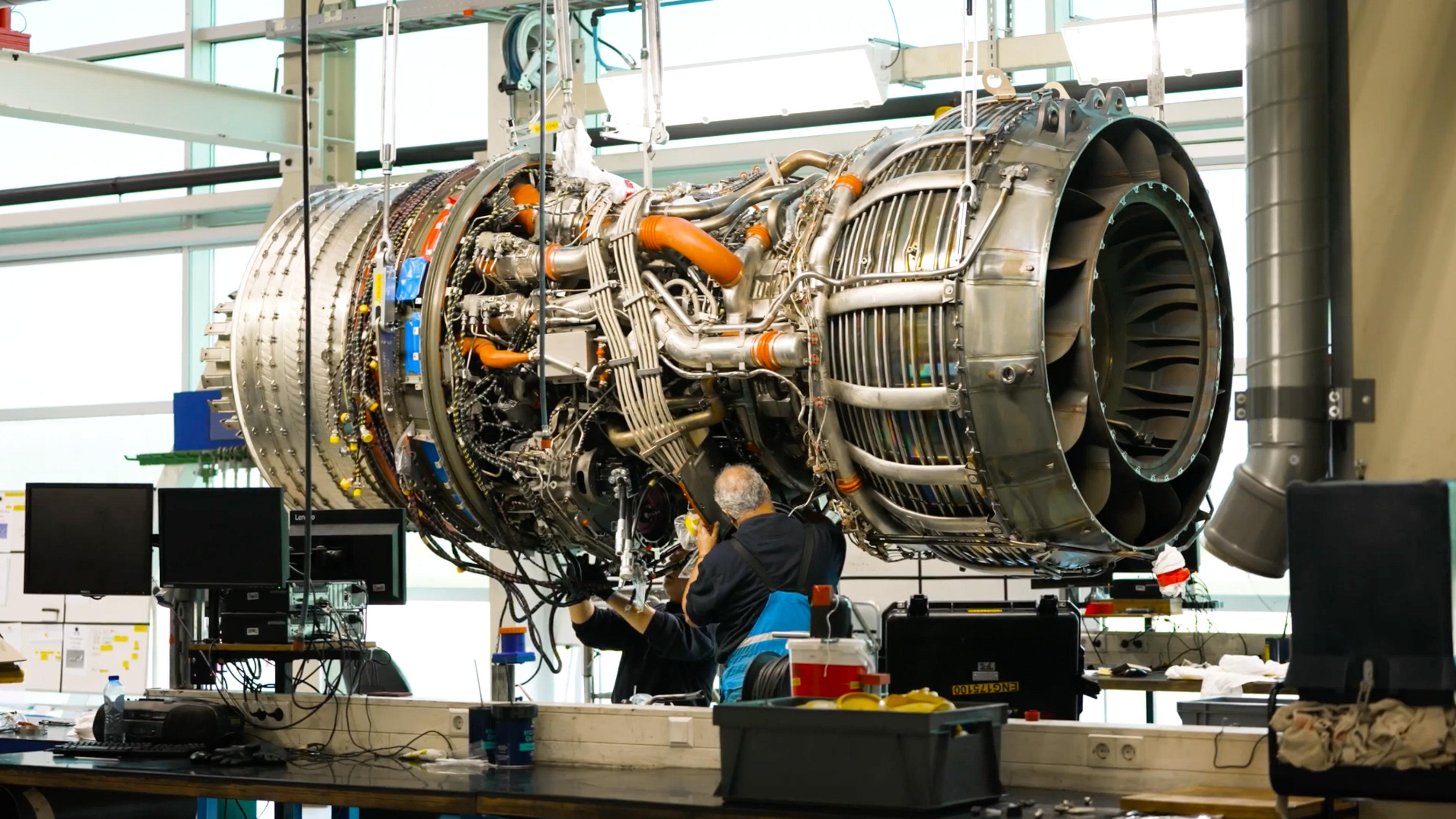

Dozens of KLM aircraft take to the skies every day. The flight schedule is tight, so it's all the more important that technical defects are fixed quickly and properly. At Repair, we repair and rework engine parts. Often, an inspection or thorough cleaning is enough, but sometimes there is more work to be done such as turning, milling, or welding, for example. And we can use some extra help with that. Have you got two right hands, do you work meticulously, and do would you like to work in an international and innovative environment?Then come on board!

Meet the team

At Repair, we inspect, repair, and rework aircraft engines. And that is quite a precise job, because they consist of thousands of often minuscule parts. First we do a thorough inspection, followed by a special cleaning. After this thorough cleaning, the parts go to the repair shop for a number of processing steps, such as plasma spraying, welding, turning, or milling.

Unique in the market

At Repair, we work in teams of up to 15 colleagues, managed by a team leader. Diversity is important to us, both in age and background, but also within our work. We're at home in all markets, we can do benchwork, paint, weld, you name it! All the work we do at Repair has one thing in common, it's unique in the aviation world. We carry out repairs that can and may only be done at KLM. That's why international companies regularly knock on our door with apparently unsolvable technical defects. So we work not only for KLM and Air France, but also for dozens of other airlines.

Repair at a glance

Number of colleagues: 240

Division: Engineering & Maintenance (E&M)

Department: Engine Services

Home base: KLM-building 410 at Schiphol-Oost

Work hours: Dag shift or evening shift

Newer, better, faster

We not only carry out existing repairs, but also develop new ones. Repair development, we call that. We are constantly looking at how we can further develop our department. We do this by investing in innovative machinery and robotisation, for example, we now have our heaviest parts lifted by a robotic arm. We're currently looking into how we can use AI to inspect engine parts by setting up an automated 'inspection lane'. All ways to work faster, better and more efficiently, and to shape the future of Repair.

Open vacancies

Scrum Master Engineering & Maintenance

Technical40 hoursLicensed Engine Mechanic

Technical40 hoursAircraft Maintenance Technician B1 or B2

Technical32-40 hours