Engine Mechanic

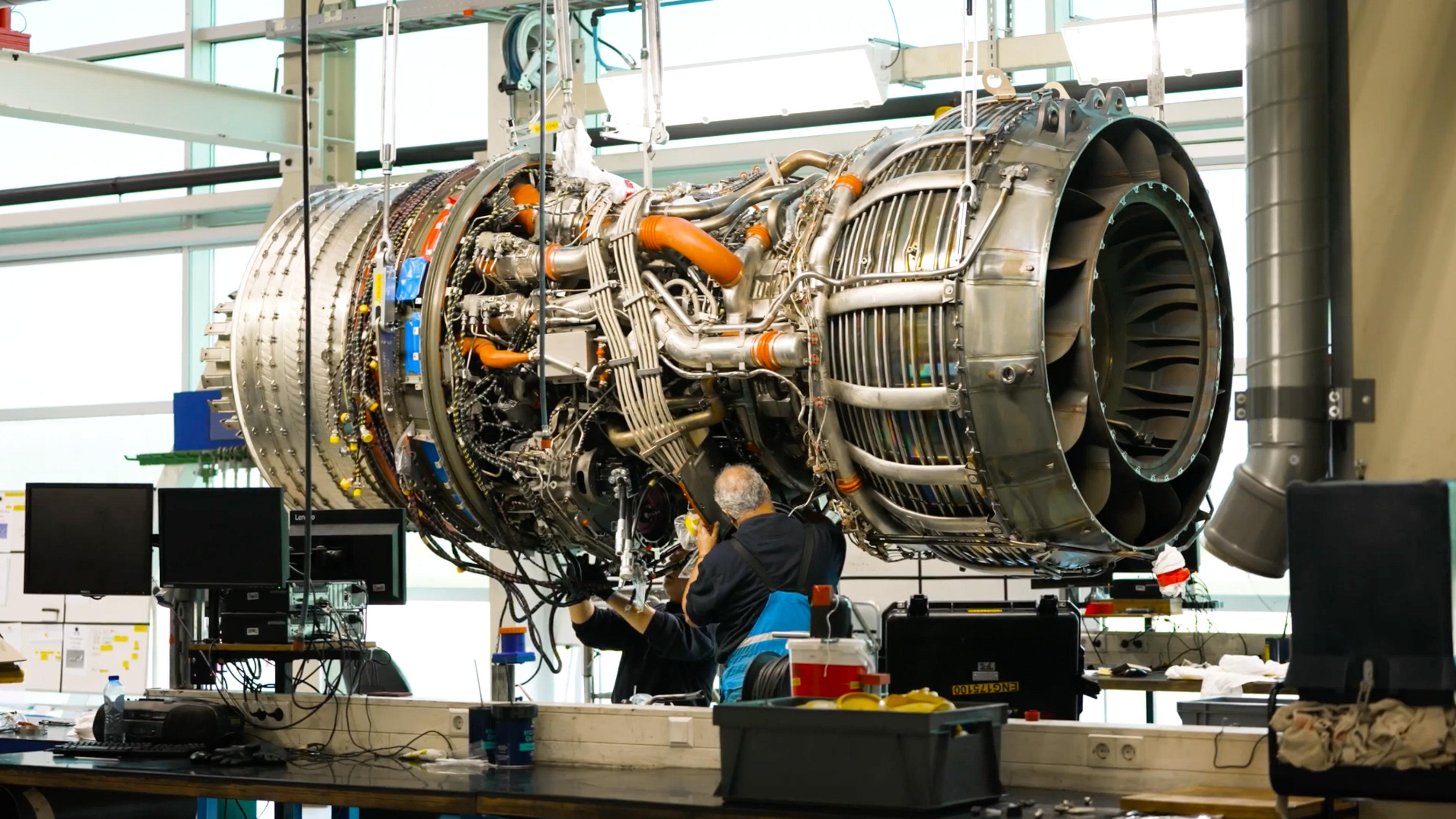

Always wanted to know what it’s like to see an aircraft engine up close – and actually work on one yourself?

At Engine Services, you now have that chance. Thanks to our new training approach, you can make the transition from technician to aircraft engine mechanic. Whether you have experience in electrical engineering, mechanical engineering, or as a car mechanic: your technical background is the perfect foundation. This allows you to advance to XXL-level maintenance of the engines that keep our aircraft safe and on time in the air. From large-scale inspections to precision work on the smallest parts: here, we work with absolute focus on quality and safety.

Working in the Engine Shop

A technical problem or time for a full check-up? In both cases, you’ll first carefully disassemble the engine. Next, you’ll inspect all the parts – from the largest turbines to the smallest bolts – and service or replace what’s necessary. You’ll detect anomalies, carry out repairs, and then reassemble the engine perfectly.

As an aircraft engine mechanic:

- You’ll learn to (dis)assemble and work on various engine components;

- You’ll work on engines such as the CFM56-7B, CF6, GEnx, and LEAP;

- You’ll always follow strict safety procedures.

What does your training look like?

We provide step-by-step training via the Engine Academy:

- Bootcamp (6 weeks)

You’ll learn the basics: how Engine Services is organized, how to process work orders, and how to identify anomalies. - Specialization (a few weeks)

Outside of production, you’ll practice on a Boeing 737 engine, for example on the gearbox or the low-pressure turbine. - Practice (up to 1.5 years)

You’ll join your team and, under the guidance of a practical supervisor, work on engines from KLM and other airlines. - Qualified Engine Mechanic (after approx. 3 years)

This means you’re allowed to work on engines independently and check and sign off on colleagues’ work. Your tasks will be varied and challenging, including:

- Removing the low-pressure turbine from a CFM56

- Balancing the high-pressure compressor rotor of a GEnx

- Assembling a turbine rear frame of a LEAP-1B

- Conducting a borescope inspection after engine testing

- Solving urgent issues with an engine installed under the wing at an outstation

Why should you take this opportunity at KLM?

Because with us, you’ll not only be working on the most powerful engines in the world, but you’ll also:

- Start working in the Engine Shop right away;

- Get paid from day one;

- Work in a team of 20 colleagues;

- Get substantial discounts on airline tickets (if you’ve been employed for at least 6 months);

- Enjoy plenty of opportunities to grow further.

Some possible next steps:

- Become certifying staff. Later, you can even grow to lead mechanic, where you’ll be responsible for the entire assembly process of the project.

- Test engines in the test cell on site.

- Inspect engine parts for conformity and decide whether parts can last another 5,000 flights or need complex repairs.

Where you will land

Engine Services is part of KLM Engineering & Maintenance – one of the largest and most versatile technical organizations in the Netherlands. Here, we maintain engines from the KLM fleet and from about 200 customers worldwide. We work on engines such as the GEnx-1B (Boeing 787) and the CFMI LEAP-1A (Airbus A320 NEO) and 1B (Boeing 737 MAX), but also the CF6 and the CFM56-7B.

Open vacancies

Line Maintenance Mechanic (CAT A)

Technical40 hoursAircraft Mechanic

Technical40 hoursAircraft Maintenance Technician B1 and/or B2

Technical32-40 hours